45#钢特性|交货状态|正火|回火|淬火|调质.

一、45#钢板读作:四十五号钢

二、45#钢板对照牌号:中国GB标准钢号45;日本JIS标准钢号S45C/S48C;德国DIN标准材料钢号1.0503;德国DIN标准钢号C45;英国BS标准钢号IC45/080A47;法国AFNOR标准钢号CC45,国际标准化组织ISO标准钢号C45E4。

三、45#钢板执行标准:GB/T711/WTB

No. 45 steel plate as standard

四、45#钢板的产地:舞阳钢铁

Origin of 45# steel plate: Wuyang Steel

五、45#钢板交货状态:正火、回火、淬火、调质

45# steel plate delivery status: normalizing, tempering, quenching and tempering

①、正火N:将钢板加热到适宜温度在空气中冷却

②、回火T:将钢板在某一适当温度下进行长时间保温在冷却

③、淬火Q是将钢板加热保温和在水油或其他无机盐等介质中快速冷却

④、调制:N+T 正火加回火

⑤、45号钢淬火后没有回火之前,硬度大于HRC55(最高可达HRC62)为合格。

⑥、实际应用的最高硬度为HRC55(高频淬火HRC58)。

⑦、45号钢不要采用渗碳淬火的热处理工艺。

六、45#钢板Z向性能可提供Z15、Z25、Z35

45# steel Plate Z provides Z15, Z25, Z35 for performance

Z向:是厚度方向性能钢板的俗称对于较厚的钢板对其厚度方向的力学性能有特殊规定

七、45#钢板也可提供探伤:

Flaw detection is also available for 45# steel plates

超声波检验,又叫超声波探伤,是针对钢板内部重量进行检验的一种方法手段,可以检验钢板内部的缺陷如(隐蔽裂纹,气孔,沙眼,杂质等)分别为Ⅰ探、Ⅱ探、Ⅲ探

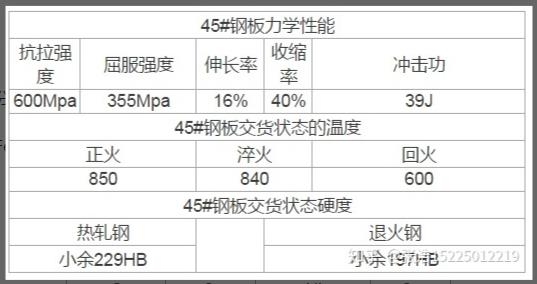

八、力学性能、

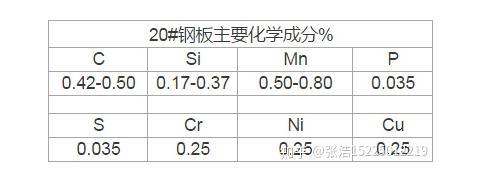

九、化学成分

主要成分为Fe(铁元素),且含有以下少量元素:

C:碳; Si:硅; Mn:锰; P:硫;

S:磷; Cr:铬; Ni:镍; Cu:铜

密度7.85g/cm3,弹性模量210GPa,泊松比0.269。

十、45#钢板特性

No. 45 steel plate characteristics commonly used carbon quenched structural steel. The steel is generally cold plastic, annealing and normalizing are better than tempering, it has higher strength and better machinability, after proper heat treatment, certain toughness, plasticity and wear resistance can be obtained, and the material source is convenient. Suitable for hydrogen welding and argon arc welding, not suitable for gas welding. It is necessary to preheat before welding and stress relief annealing after welding. Normalizing can improve the cutting performance of blanks with hardness less than 160HBS. After quenching and tempering treatment, the comprehensive mechanical properties of the steel should be optimized for other medium carbon structural steels. However, the steel has low hardenability, critical quench diameter in water is 12~17mm, and cracking tendency occurs when water quenching. When the diameter is larger than 80mm, the mechanical properties are similar after tempering or normalizing, and the medium and small die parts can obtain higher strength and toughness after tempering, while the large parts should be normalized. Therefore, this steel is usually used in the state of tempering or normalizing.

十一、.处理要求

45钢调质硬度在HRC20~HRC30之间;

45钢淬火硬度在HRC55~58之间,极限值可达HRC62;

45钢要放置15-20天才能使用,是因为要进行时效处理,使钢的性能稳定下来,

实际应用的最高硬度为HRC55(高频淬火HRC58)。

十二、用途

HRC是48-55,机械上用的比较多,用以制造蒸汽透平机、压缩机、泵的运动零件;还可代替渗碳钢制造齿轮、轴 、活塞销等零件(零件需经高频或火焰表面淬火);并可用作铸件。

45钢为优质碳素结构用钢,硬度不高易切削加工,模具中常用来做模板,梢子,导柱等,但须热处理。调质处理后零件具有良好的综合机械性能,广泛应用于各种重要的结构零件,特别是那些在交变负荷下工作的连杆、螺栓、齿轮及轴类等。但表面硬度较低,不耐磨。可用调质+表面淬火提高零件表面硬度。