镍基耐腐蚀合金材料的化学成分和性能用途

Nickle based corrision alloy seamless tube

· 用途:应用于化学和石化行业以及海洋开发制造加热器、换热器、蒸发器、冷凝器以及输送管线等。

· Usage: widely used in manufacturing of petrochemical industry and ocean exploitation such as heater, heat exchanger, evaporator, condensator and line of pipe, etc.

· 订货标准 standard:ASME SB163/ASME SB167/ASME SB407/ASME SB444/ASME SB622/ ASME SB423/ASME SB829 企业标准、技术协议

· 可供规格size:热挤压管 hot extrusion tube:外径OD:48-325mm;壁厚WT:4-40mm

冷加工管cold rolling tube:外径OD:5.8-273mm;壁厚WT:0.3-35mm

· 交货状态condition:热加压hot extrusion;冷加工cold rolling;热处理heat treatment

主要钢种(牌号)的化学成分和性能chemical composition and performance of main steel grade(trademark)

宝钢牌号 baosteel | ASTM UNS | 化学成分chemical composition | ||||||||||

C | Ni | Cr | Mo | Cu | Fe | Si | Mn | S | P | 其他others | ||

W% | ||||||||||||

BT200 | N02200 | ≤0.15 | ≥99.0 | / | / | ≤0.25 | ≤0.40 | ≤0.35 | ≤0.35 | ≤0.010 | ≤0.03 | / |

BT201 | N02201 | ≤0.02 | ≥99.0 | / | / | ≤0.25 | ≤0.40 | ≤0.35 | ≤0.35 | ≤0.010 | ≤0.03 | / |

BT400 | N04400 | ≤0.30 | ≥63 | / | / | 28/34 | ≤2.5 | ≤0.5 | ≤2.0 | ≤0.020 | ≤0.03 | / |

BT800 | N08800 | ≤0.100 | 30.0/ 35.0 | 19.0/ 23.0 | / | ≤0.75 | ≥39.5 | ≤1.0 | ≤1.5 | ≤0.015 | ≤0.02 | Al:0.15/0.60 Ti:0.15/0.60 |

BT800H | N08810 | 0.05/ 0.10 | 30.0/ 35.0 | 19.0/ 23.0 | / | ≤0.75 | ≥39.5 | ≤1.0 | ≤1.5 | ≤0.015 | ≤0.02 | Al:0.15/0.60 Ti:0.15/0.60 Al+Ti≤0.70 |

BT800HT | N08811 | 0.06/ 0.10 | 30.0/ 35.0 | 19.0/ 23.0 | / | ≤0.75 | ≥39.5 | ≤1.0 | ≤1.5 | ≤0.015 | ≤0.02 | Al:0.15/0.60 Ti:0.15/0.60 Al+Ti≤0.85/1.2 |

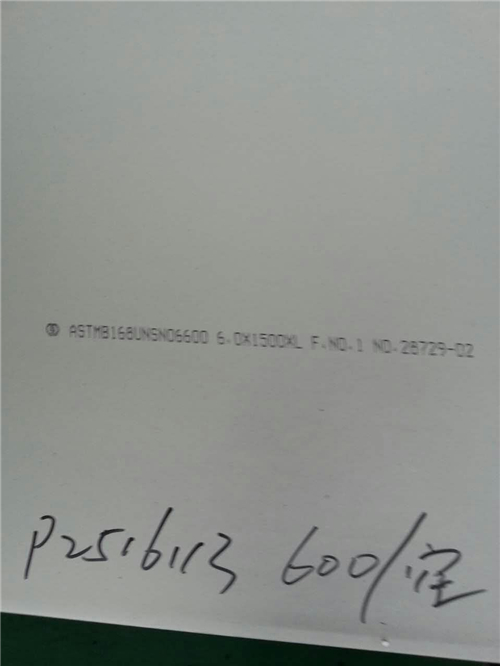

BT600 | N06600 | ≤0.150 | ≥72.0 | 14.0/ 17.0 | / | ≤0.50 | 6.0/ 10.0 | ≤0.5 | ≤1.0 | ≤0.015 | ≤0.03 | / |

BT690 | N06690 | ≤0.05 | ≥58.0 | 27.0/ 31.0 | / | ≤0.50 | 7.0/ 11.0 | ≤0.5 | ≤0.5 | ≤0.015 | ≤0.03 | / |

BG2830 | N08028 | ≤0.03 | 29.5/ 32.5 | 26.0/ 28.0 | 3.0/ 4.0 | 0.6/ 1.4 | 余 | ≤1.0 | ≤2.5 | ≤0.03 | ≤0.03 | |

BG2250 | N06985 | ≤0.015 | 余 | 21.0/ 23.5 | 6.0/ 8.0 | 1.5/ 2.5 | 18.0/ 21.0 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.03 | W≤1.5 Co≤5.0 Nb+Ta≤0.5 |

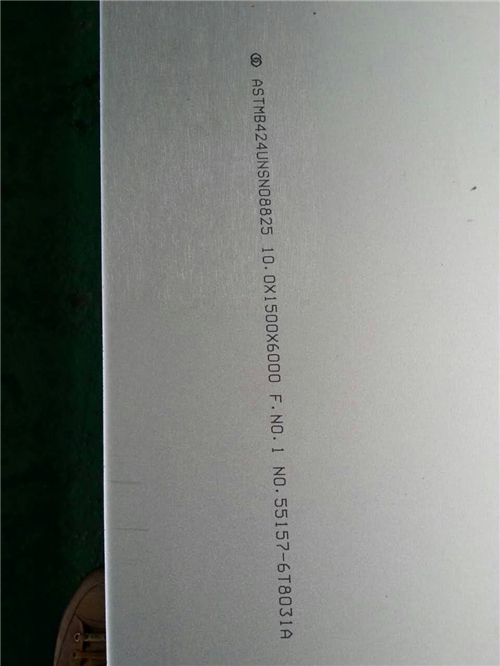

BT825 | N08825 | ≤0.050 | 38.0/ 46.0 | 19.5/ 23.5 | 2.50/ 3.50 | 1.5/ 3.0 | ≥22.0 | ≤0.5 | ≤0.5 | ≤0.03 | ≤0.04 | Al≤0.20 Ti≤0.6/1.2 |

BT625 | N06625 | ≤0.100 | ≥58.0 | 20.0/ 23.0 | 8.00/ 10.0 | / | ≤5.0 | ≤0.5 | ≤0.08 | ≤0.015 | ≤0.015 | Al≤0.40 Ti≤0.40 Nb+Ta:3.15/4.15 |

BTC276 | N10276 | ≤0.010 | 余 | 14.5/ 16.5 | 15.0/ 17.0 | / | 4.0/ 7.0 | ≤0.08 | ≤0.08 | ≤0.03 | ≤0.04 | W:3.0/4.5 Co≤2.5 V≤0.35 |

牌号对照 grade parallel table

宝钢牌号 baosteel | 美国 ASTM | 国家牌号 GB | 德国DIN | 日本JIS |

BT200 | N02200 | |||

BT201 | N02201 | 2.4068 | NW2201 | |

BT400 | N04400 | - | 1.1743 | NW4400 |

BT800 | N08800 | NS1101 | 1.4876 | NCF800 |

BT800H | N08810 | NS1102 | 1.4876 | NCF800H |

BT800HT | N08811 | - | 1.4876 | - |

BT600 | N06600 | NS3102 | 2.4816 | NCF600 |

BT690 | N06690 | NS3105 | 2.4624 | NCF690 |

BG2830 | N08028 | - | - | - |

BG2250 | N06985 | - | - | - |

BT825 | N08825 | NS1402 | 2.4858 | NCF825 |

BT625 | N06625 | NS3306 | 2.4856 | NCF625 |

BTC276 | N10276 | NS3304 | 2.4819 | NW0276 |

室温力学性能room-temperature mechanical property

宝钢牌号baosteel | 状态 condition | 抗拉强度 Rm,min,MPa | 屈服强度 Rp0.2%,min,MPa | 延伸率 A50,min,% | |

BT200 | solution | 379 | 103 | 40 | |

BT201 | solution | 345 | 83 | 40 | |

BT400 | OD≥127mm | annealing | 480 | 195 | 35 |

OD<127mm | annealing | 480 | 170 | 35 | |

BT800 | solution | 520 | 205 | 30 | |

BT800H | solution | 450 | 170 | 30 | |

BT800HT | solution | 450 | 170 | 30 | |

BT600 | OD≥127mm | solution | 550 | 205 | 35 |

OD<127mm | solution | 550 | 240 | 30 | |

BT690 | solution | 586 | 241 | 30 | |

BT028 | solution | 500 | 214 | 40 | |

BTG3 | solution | 621 | 214 | 40 | |

BT825 | solution | 586 | 241 | 30 | |

BT625 | annealing | 827 | 414 | 30 | |

solution | 276 | 690 | 30 | ||

BTC276 | solution | 283 | 690 | 40 | |

备注:BT800H,BT800HT晶粒度5级或更粗

高温力学性能high temperature mechanical property

宝钢牌号 baosteel | Mechanical property | 状态 condition | 温度 temperature℃ | |||||

350 | 450 | 550 | 650 | 750 | 850 | |||

BT800H | Rm,MPa | 固溶 solution | 485 | 490 | 480 | 420 | 270 | 149 |

Rp0.2,MPa | 162 | 165 | 169 | 155 | 125 | 95 | ||

A4.52,% | 52.5 | 56.0 | 52.5 | 50.0 | 69.5 | 101.5 | ||

BT825 | Rm,MPa | 固溶 solution | 560 | 550 | 527 | 485 | 345 | 197 |

Rp0.2,MPa | 205 | 195 | 191 | 169 | 170 | 176 | ||

A4.52,% | 47.5 | 51.5 | 49.0 | 52.5 | 64.0 | 92.0 | ||

BT625 | Rm,MPa | 固溶 solution | - | - | - | 610 | 480 | 345 |

Rp0.2,MPa | - | - | - | 210 | 225 | 215 | ||

A4.52,% | - | - | - | 96.5 | 114.0 | 117.0 | ||

物理性能physical property

宝钢牌号 baosteel | 密度 density/g·cm3 | 熔点 Metaling rane/℃ | 膨胀系数 Coefficient of expansion μm/m/℃ | 导热系数 Thermal conductivity W·(m·℃)-1 | 电阻率 Specific resistance μΩ·m | 弹性模具 Modulus of elasticity GPa | ||

100℃ | 300℃ | 25℃ | 300℃ | 20℃ | ||||

BT400 | 8.80 | 1300-1350 | 14.2 | 15.2 | 22.0 | 26.9 | 0.51 | 26.0 |

BT800 | 7.94 | 1357-1385 | 14.1 | 16.2 | 11.5 | 16.3 | 0.989 | 196.5 |

BT600 | 8.47 | 1354-1413 | 10.4 | 14.2 | 14.9 | 19.0 | 1.03 | 214.0 |

BT690 | 8.19 | 1343-1377 | 14.06 | 14.53 | 13.5 | 17.3 | 1.148 | 211.0 |

BG2830 | 8.0 | - | 15.0 | 15.9 | 11.4 | 15.3 | 0.99 | - |

BG2250 | 8.14 | 1260-1343 | 14.6 | 14.6 | 10.0 | 15.9 | 1.12 | 199.0 |

BT825 | 8.14 | 1370-1400 | 14.1 | 15.3 | 11.1 | 15.4 | 1.13 | 196 |

BT625 | 8.44 | 1290-1350 | - | - | 9.8 | 14.1 | 1.29 | 204.8 |

BTC276 | 8.89 | 1325-1370 | 12.2 | 12.9 | 11.2 | 14.7 | 1.22 | 205 |

晶间腐蚀性能intergranular corrosion resistance

按ASTM G28A法(硫酸铁-硫酸法)测定的腐蚀速率

Intergranular corrosion resistance according to ASTM G28(ferric sulfate- sulfuric acid method)

钢种 grade | 状态 condition | 时间 (h) | 腐蚀速率 mm/a | 腐蚀深度 (μm) |

BT800 | 固溶 solution | 120 | 0.42 | - |

BT800H | 120 | 1.464 | - | |

BT600 | 120 | 0.96 | - | |

BT825 | 120 | 0.324 | ≤50 | |

BT625 | 120 | 0.535 | ≤50 |

按ASTM 262C法65%硫酸法测定的腐蚀速率

Intergranular corrosion resistance according to ASTM 262(65% HNO3)

钢种 grade | 状态 condition | 腐蚀速率corrosion rate(mm/a) | 平均腐蚀深度 corrosion rate(mm/a) | ||||

一 | 二 | 三 | 四 | 五 | |||

时间/48h | 时间/48h | 时间/48h | 时间/48h | 时间/48h | |||

BT600 | 固溶 solution | 0.288 | 0.30 | 0.324 | 0.432 | 0.528 | 0.371 |

BT800H | 0.204 | 0.12 | 0.168 | 0.252 | 1.02 | 0.348 | |

BT825 | 0.348 | 0.204 | 0.24 | 0.192 | 0.312 | 0.264 | |

BT625 | 0.556 | 0.454 | 0.489 | 0.466 | 0.471 | 0.489 | |

应用Application

氟化工用反应器BT600

多晶硅加热器BT800H

石化空冷器BT825